PRODUCTS

MT 100 Collar Forming Machine

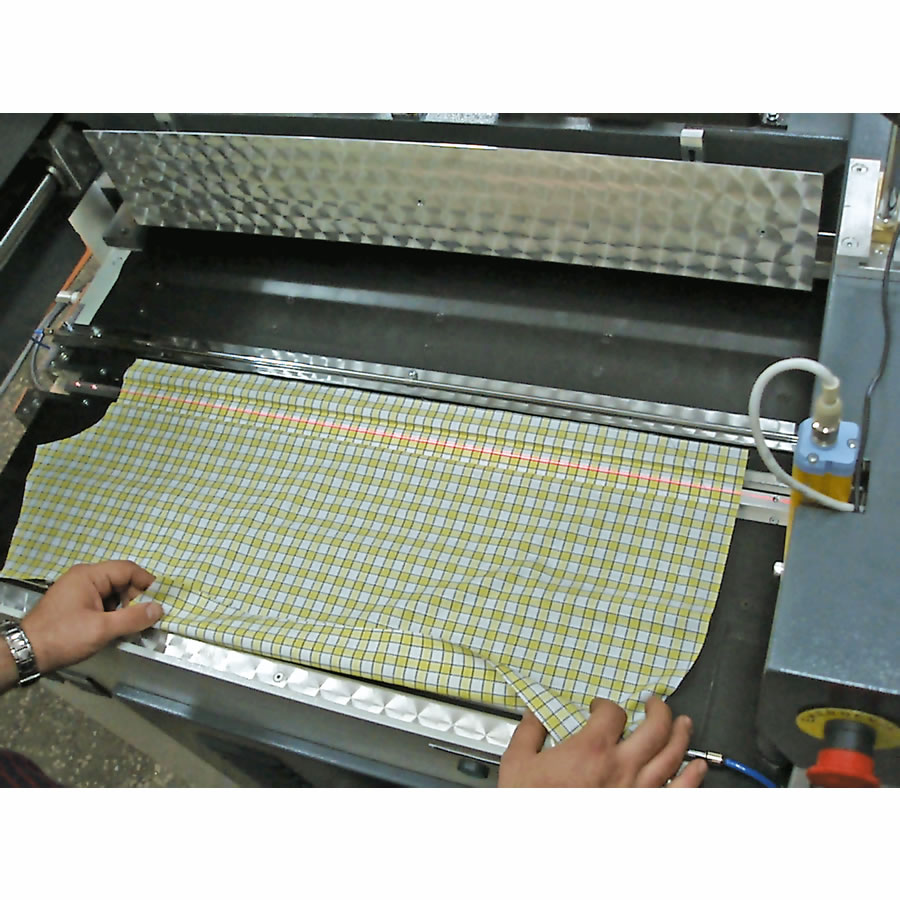

7 August 2018MT 602 Shirt Front Placket Pressing & Creasing Machine

Works with electro-pneumatic supply. Good quality with high performance combines with easy operation. Folding can be from 1cm to 8cm thickness. Interface can also be pressed. It is economic as only one operator is necessary to operate the machine and up to 3000 pcs/shigt can be pressed in one day.

Laser line helps the positioning of fabric with line. Short sleeve pressing can also be made.

When the start buttons are pushed after positioning the fabric on the folding station, pressing mold moves, holds the folded fabric with vacuum and deliveres to pressing station. When the pressing time is out upper mold gets the fabric to the stacking station. These cycles are continuous. The sensors controls the level of stacked products and if necessary it reduces the height of the lift to prevent jamming.

TECHNICAL INFO

Weight: 520kg

Compress Air: 6 Bar

Dimensions: 1430x1570x1660mm

Electrical: 380V

Electrical Consumption: 6,5kw

Capacity: 360 pcs/hour

Ironing Temperature: 110 ̊C – 150 ̊C