MOST VIEWED PRODUCTS

USTUN MACHINERY continuously innovates in production and continues its operations according to customer requirements.

It achieves a reliable identity and a large customer potential in the sector through its history that is approximately 30 years.

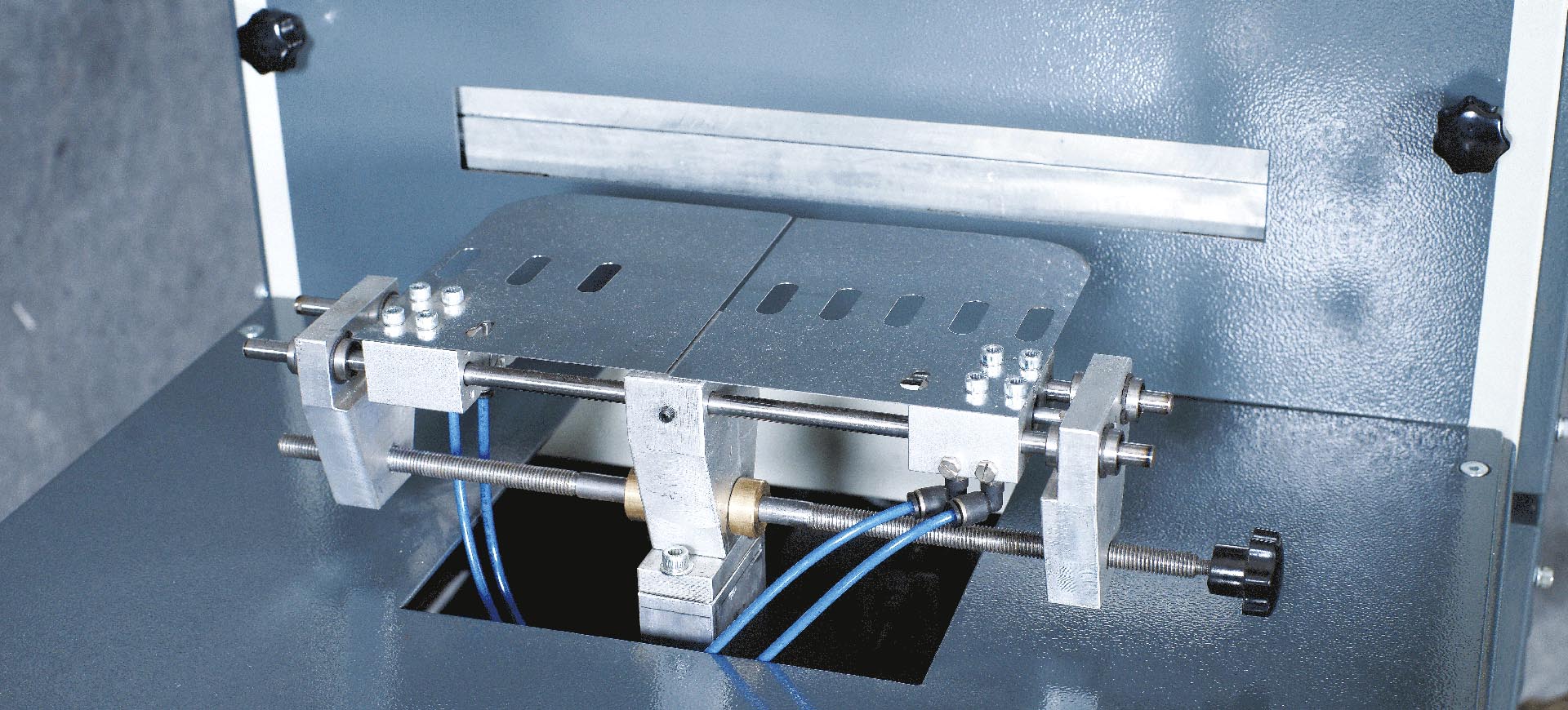

Collar Forming Machine

It guarantees that all of collar models have high-quality collar end because the right and left ironing areas independent and angular. Thanks to specially-designed pneumatic operating system, a holder system is not needed that it prevents the collar from slipping. Therefore, it doesn’t produce any mark which may be caused by the holder system. It has independent heating control system and independent pressing time setting. It has a practical pattern change possibility. It irons 2500 collars per 8 hours approximately.

Detail

Pressing Machine For Sleeve Plackets

Easy PLC control with multifunctional LCD display. 3000 pcs/shift capacity can be obtained with latest technology. PLC controlled heating control system. Sleeve plackets and bias tape ironing is possible. After the fabric is positioned on the mold, it is transfeared to the stacking station. The machine is easy to operate as it is fully automatic. Any kind of fabric is well positioned by the help of laser line. Mold can be adjusted for some details such as stitching marks.

Detail

Shirt Front Placket Pressing & Creasing Machine

Works with electro-pneumatic supply. Good quality with high performance combines with easy operation. Folding can be from 1cm to 8cm thickness. Interface can also be pressed. It is economic as only one operator is necessary to operate the machine and up to 3000 pcs/shigt can be pressed in one day. Laser line helps the positioning of fabric with line. Short sleeve pressing can also be made.

Detail